Model Driven Technology for full system test verification

D4T

Systems provides the

customerh a fully

integrated test automation tool to validate the test setup for the customer DUT on a customer selected tester platform.

Our tools

are positioned to tackle test during the

design phase in the IC

product

creation process, while maintaining interaction with the standard

analog design and simulation environment. The methodology incorprates a

link to standard test procedures in test

engineering running at various ATE platforms enabling a

flawless test development flow. The methodology and tool

technology connect the design and test community in analog IC

design.

Our solution offers customers reduction of test cost, while increasing the test quality and accelerating the time-to-market, all achieved by: flexible

approach in which the test plan can be

verified and validated at pre-silicon. To enable this simulation based

test flow, D4T applies a model based approach to all components

relevant in a test setup. The tool flow identifies 4 high level

components, each of which is integrated in the tool as a model with

different abstraction levels. The test description model is an user

specified implementation of the industrial test specification for every

test applied to the DUT. Not only simulation time for a full

system setup is now within acceptable time limits, but by modeling each

component in the setup it obtains a highly accurate prediction of the

actual test response.

flexible

approach in which the test plan can be

verified and validated at pre-silicon. To enable this simulation based

test flow, D4T applies a model based approach to all components

relevant in a test setup. The tool flow identifies 4 high level

components, each of which is integrated in the tool as a model with

different abstraction levels. The test description model is an user

specified implementation of the industrial test specification for every

test applied to the DUT. Not only simulation time for a full

system setup is now within acceptable time limits, but by modeling each

component in the setup it obtains a highly accurate prediction of the

actual test response.

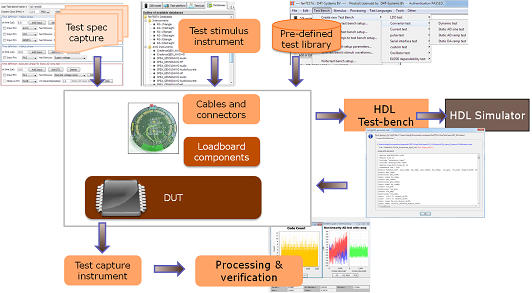

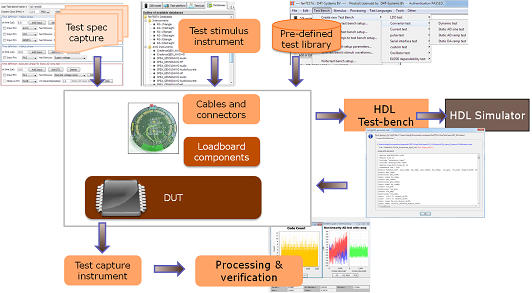

Going one step deeper in the flow, the architecture of the model driven test method becomes clear. Test stimuli, test description and test setup are all provided by the tool in a comprehesive fashion making use of advanced models for each component. The user generates, once all test parameters and test setups are defined, the HDL test bench which become an input for a 3rd party EDA simulator. The test bench includes data files that represent the real signal content of the full test environment. This way, the tool extends the DUT performance with all commonly used peripheral test hardware, constituing the non-ideal signal sources, test mode settings and loadboard/interconnect signal conditioning. Now, the simulation can be run taking into account electrical and physical limitations of all these components.

The architecture is created in such a way that the test bench definition can be created fully independent of the EDA environment.

The test outcome is, as if it was running on the hardware. In the end,

processing is applied to derive standard test metrics commonly used for

standard test specification. This is integrated within the toolbox

including statistics where applicable.

Our solution offers customers reduction of test cost, while increasing the test quality and accelerating the time-to-market, all achieved by:

- Full analog test validation: from test specification at IP level to the System level towards the Tester platform.

- Integrating and validating analog test during design cycle.

- Up and running test plan before silicon tape-out

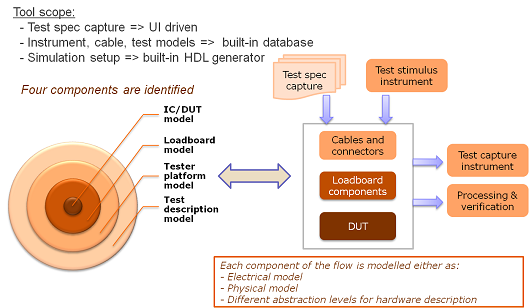

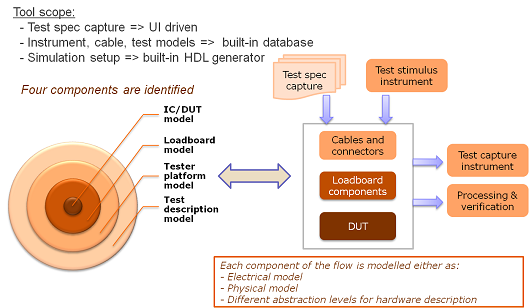

Model driven tool architecture

The test approach for mixed signal circuits is based on creating the test benches early in the design phase. By integrating the test automation into the design flow, D4T offers a highly flexible

approach in which the test plan can be

verified and validated at pre-silicon. To enable this simulation based

test flow, D4T applies a model based approach to all components

relevant in a test setup. The tool flow identifies 4 high level

components, each of which is integrated in the tool as a model with

different abstraction levels. The test description model is an user

specified implementation of the industrial test specification for every

test applied to the DUT. Not only simulation time for a full

system setup is now within acceptable time limits, but by modeling each

component in the setup it obtains a highly accurate prediction of the

actual test response.

flexible

approach in which the test plan can be

verified and validated at pre-silicon. To enable this simulation based

test flow, D4T applies a model based approach to all components

relevant in a test setup. The tool flow identifies 4 high level

components, each of which is integrated in the tool as a model with

different abstraction levels. The test description model is an user

specified implementation of the industrial test specification for every

test applied to the DUT. Not only simulation time for a full

system setup is now within acceptable time limits, but by modeling each

component in the setup it obtains a highly accurate prediction of the

actual test response. Going one step deeper in the flow, the architecture of the model driven test method becomes clear. Test stimuli, test description and test setup are all provided by the tool in a comprehesive fashion making use of advanced models for each component. The user generates, once all test parameters and test setups are defined, the HDL test bench which become an input for a 3rd party EDA simulator. The test bench includes data files that represent the real signal content of the full test environment. This way, the tool extends the DUT performance with all commonly used peripheral test hardware, constituing the non-ideal signal sources, test mode settings and loadboard/interconnect signal conditioning. Now, the simulation can be run taking into account electrical and physical limitations of all these components.

The architecture is created in such a way that the test bench definition can be created fully independent of the EDA environment.

- This eases the task for a test engineer who may not be proficient with an EDA tool.

- It has the advantage that DUT IP can be protected since it

does not need to be shared with a potentially outsourced test

development project. .

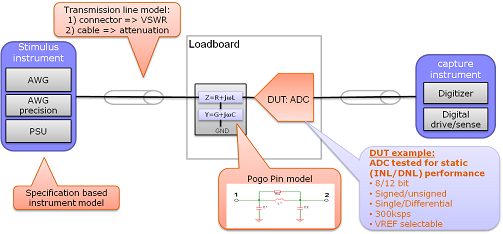

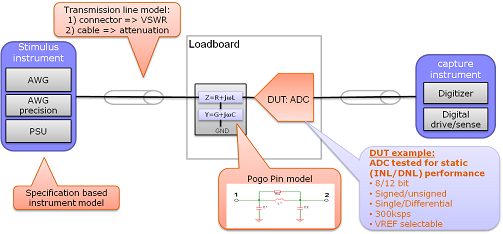

A simple test setup example using the model driven methodology

A commonly used test in production testing is the ADC static testing where INL, DNL, offset and gain are the test metrics for the ADC. Though simple in setup, the picture shows all elements provided and modeled by the tool architecture. This is a common case of a full test validation that can be done by including all peripheral hardware used in production testing. The architecture components comprise now:- Test description model: the settings for ADC static linearity test. Power up sequence and test mode control. Pin selection for ADC register access and data word capture. It also inlcudes the pre-defined post processing for INL and DNL metrics.

- Tester Platform model: the test stimuli (up/down ramp) generated by an AWG or PSU model. At the capture side, a digital sense instrument model is applied to capture the ADC words at specified word sample rate.

- Loadboard model: depending on complexity of loadboard this model contains generally a model for simple resistors, filters or possibly transmission lines. The cable interconnect between tester and loadboard uses the tool library physical models which includes bandwidth limited attenuation.

- IC/DUT model: this is a customer provided abstract model of the DUT which resides in the EDA database. Customers may also choose to run the simulation on the transistor level at the expense of higher simulation times.